The Different Kinds Of Earth Anchors for Your Building Requirements

The Different Kinds Of Earth Anchors for Your Building Requirements

Blog Article

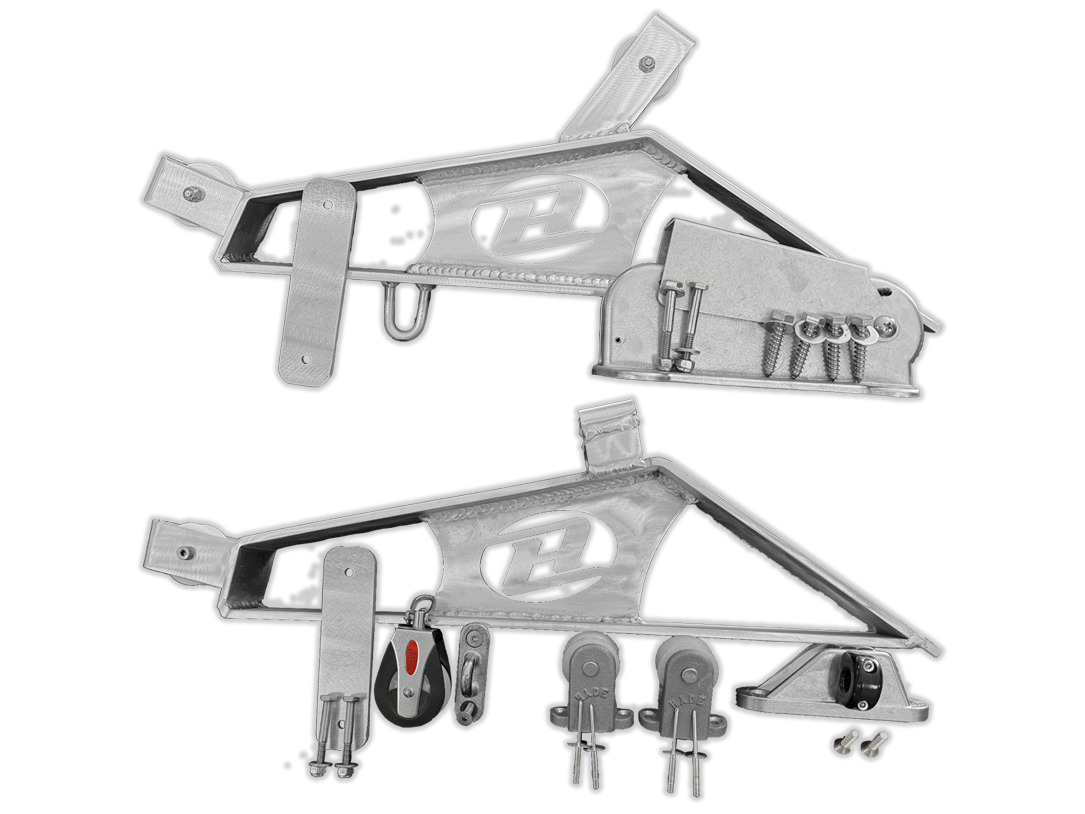

High-Performance Anchor Systems for Any Kind Of Application

High-performance anchor systems are essential in making certain safety and stability across a multitude of applications, from building to aerospace. Understanding the nuances of various support kinds and their corresponding setup strategies is vital.

Kinds Of Anchor Equipments

When taking into consideration the varied applications of support systems, what are the key kinds that professionals depend on for high-performance outcomes? Support systems can be generally classified right into numerous kinds, each made to fulfill specific requirements based on the nature of the load and ecological problems.

The initial category is mechanical supports, that include development supports, wedge supports, and screw anchors. These are normally utilized in concrete and stonework applications, supplying durable holding power with mechanical interlock or friction.

Another significant type is sticky supports, which utilize chemical bonding representatives to secure the support within the substratum. This kind is specifically useful in applications where high tensile toughness and resistance to shear forces are essential.

Furthermore, there are passive anchors, such as deadman supports, which rely upon the weight and resistance of bordering products to secure objects. They are often made use of in exterior applications or where vibrant lots are existing.

Last but not least, there are specialized anchor systems like ground supports, which are made use of in civil engineering and building and construction projects for maintaining frameworks. Each kind of anchor system is made with certain performance metrics in mind, making sure ideal safety and security and efficiency across different applications.

Trick Features and Advantages

High-performance anchor systems offer a series of essential functions and benefits that improve their effectiveness in different applications. One of the main attributes is their premium lots ability, which guarantees security and security under considerable tension problems. This is achieved with advanced products and design designs, permitting for trusted performance sought after environments.

In addition, these systems often incorporate innovative innovation such as rust resistance and adaptability to different substratums. This not only expands their life expectancy yet also decreases upkeep prices, making them an economical remedy over time. The flexibility of high-performance support systems permits for seamless integration into various structures, enhancing their usability across numerous projects.

One more noteworthy benefit is simplicity of installment. Numerous high-performance supports are designed for fast and uncomplicated implementation, reducing labor time and boosting overall task performance. Their lightweight nature helps with transport and handling, contributing to structured procedures.

Applications in Various Industries

In the transport market, high-performance anchors are used to protect roadway and rail facilities, adding to the safety of travelers and cars. Their dependability is paramount in stopping architectural failures that might bring about disastrous crashes. Additionally, in the eco-friendly energy market, these anchors are important for securing wind generators and photovoltaic panel installments, guaranteeing they withstand ecological anxieties while making the most of performance.

The aerospace sector likewise utilizes advanced securing options to secure elements during production and transport, where accuracy and integrity are necessary. In each of these applications, the choice of ideal support systems can dramatically affect total project success, highlighting the adaptability and necessity of high-performance anchors across numerous industrial landscapes.

Installation Techniques and Tips

Appropriate installation of high-performance anchor systems is critical to their effectiveness and long life. To make certain optimal performance, it is necessary to follow well established installment methods tailored to the specific kind of support system and application.

Begin by extensively assessing the installment website, consisting of the substratum conditions, load requirements, and environmental variables. Precise dimensions and placement are vital; utilize laser levels or plumb lines to preserve precision. When drilling, select the suitable bit size and type for the support system, making sure clean and accurate holes to avoid product damages.

Use the suggested torque settings during fastening to avoid over-tightening or under-tightening, which can jeopardize the support's honesty. Additionally, comply with the maker's standards relating to spacing and side distances to take full advantage of tons distribution and lessen potential failure factors.

Always use individual safety tools (PPE) throughout the installation process, and think about making use of specialized tools made helpful resources for high-performance anchors to improve performance and safety. Ultimately, perform an extensive evaluation post-installation to validate that all components are securely attached and abreast, making certain the anchor system is prepared to perform under anticipated tons. Earth Anchor.

Maintenance and Safety Factors To Consider

To guarantee the longevity and reliability of anchor systems, regular maintenance and security considerations need to Visit This Link be prioritized. Regular examinations are vital to identify wear and tear, deterioration, or any architectural deficiencies that might compromise the anchor's efficiency. A detailed upkeep routine should consist of examining the stability of support components, such as bolts, welds, and plates, and making sure that all links are safe and secure.

In addition, environmental variables can significantly affect support systems. For instance, exposure to harsh climate condition or harsh compounds can speed up damage. Using protective coatings or utilizing corrosion-resistant materials can improve durability and prolong service life.

Safety and security factors to consider are critical; users need to stick to supplier standards relating to tons limitations and operational procedures. Educating employees on correct use and potential dangers is vital in stopping crashes. Implementing a safety administration system that includes routine drills and feedback devices can cultivate a society of security.

Conclusion

In conclusion, high-performance anchor systems represent an important technology throughout numerous markets, offering phenomenal tons capacity, corrosion resistance, and adaptability. Routine upkeep and comprehensive examinations further improve their efficiency, developing these support systems as vital components in securing structures and equipment.

High-performance support systems are critical in making certain safety and security and security across a wide range of applications, from construction to aerospace.High-performance anchor systems provide an array of vital features and advantages that enhance their efficiency in More about the author different applications. The flexibility of high-performance anchor systems permits for seamless integration into different frameworks, improving their use throughout various tasks.

In varied industries, high-performance anchor systems play a crucial duty in guaranteeing architectural honesty and safety (Earth Anchor).In conclusion, high-performance anchor systems represent a critical technology throughout multiple markets, providing outstanding load capacity, rust resistance, and convenience

Report this page